ARSOFT and Maxi Industries present results of phase 2 of the XRWorMs project

Both companies participated in a virtual demonstration workshop organized by FaCyL, the Automotive and Mobility cluster of Castilla y León, where they presented the results of the second phase of the XRWorMs Project.

A prototype machine alert system was developed based on wearable devices integrated with visualization and operator guidance systems using extended reality (XR).

In addition, an extra layer of cybersecurity has been implemented in the IIoT communication.

The Automotive and Mobility Cluster of Castilla y León, FaCyL, has presented to its partners the results of the second phase of the XRWorMs project, a proposal driven by ARsoft and Industrias Maxi, two of the companies that make up the cluster. This project is co-financed by the Ministry of Industry and Tourism through the line of support for innovative business clusters, in its call for proposals for 2023, as part of the Recovery, Transformation and Resilience Plan.

The objective of this initiative is the simplification of industrial digital twins associated with machines, facilitating human-machine interaction. In this sense, it has been highlighted that the industrial sector is currently investing in the development of digital twins with the sensorization of its assets and the generation of IoT data. However, most of these developments do not involve workers as key actors in the process. This is where the work developed by ARsoft and Maxi Industries stands out.

Thanks to the machine status identification system included in the software tool developed in the first part of the project (and presented last April), operators can manage an industrial plant, a production line or individual machines in a simpler and more efficient way.

The second phase of the project has taken another step forward in the implementation of extended reality technology to connect machines with people. A prototype has been developed to respond to machine operation alerts, based on the use of smartwatches integrated with visualization and operator guidance systems using extended reality (XR). It has also implemented an additional layer of cybersecurity in IIoT (Industrial Internet of Things) communications.

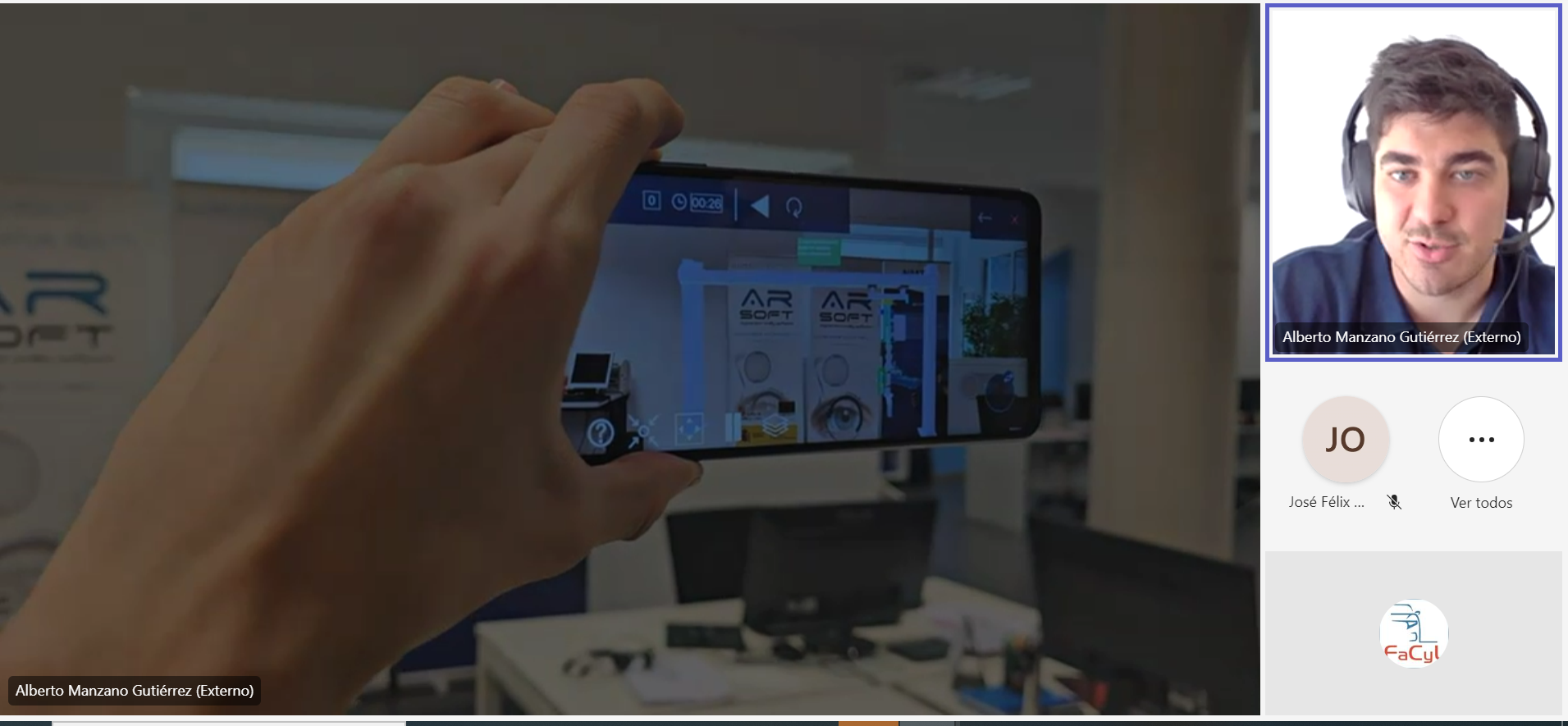

Demonstration Workshop

The managers of both companies demonstrated in this workshop how the developed prototype allows an operator to connect with the virtual twin through the extended reality (XR) visualization system. The participants of this workshop were able to test the operation of the system of alerts and operator guidance to resolve machine incidents, using smartwatches to receive such alerts and Hololens glasses to visualize the information and guidance processes. The aim is to facilitate the work of operators to improve predictive and corrective maintenance of machines.

The demonstration workshop held to present the results of phase 2 of the project was attended by around thirty professionals from the regional automotive and mobility ecosystem.